|

|

|

|

|

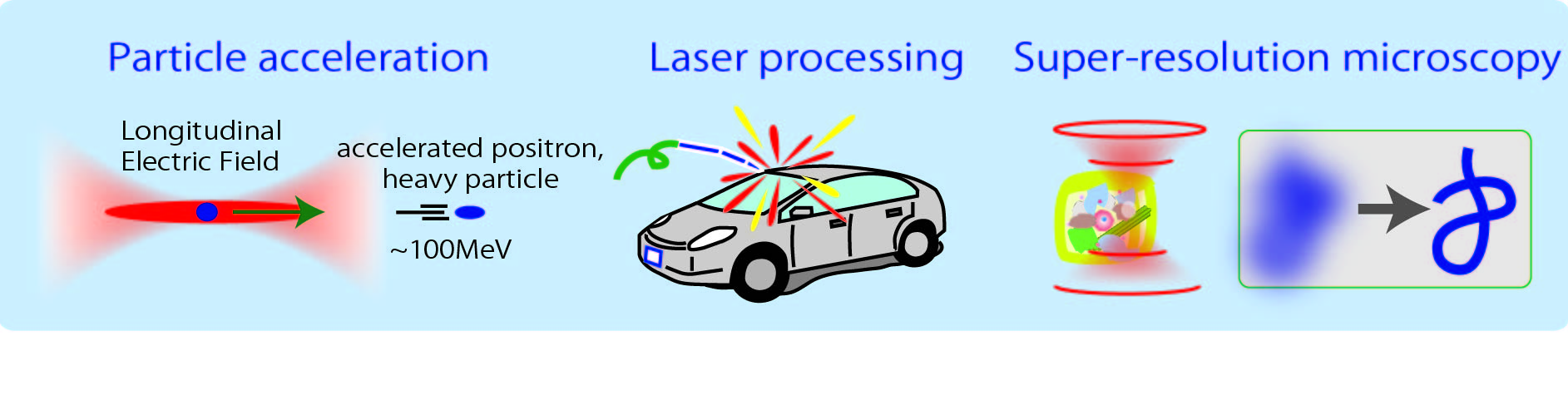

Particle

acceleration, laser processing and superresolution microscopy are

promising applications of vector beams. We are exploring the ability of

small focal spot formation of vector beams for superresolution optical

microscopy, which can achieve the spatial resolution around 100 nm by

simply replacing a conventional laser source to a vector beam (10.1016/bs.po.2021.01.001).

Super-oscillation of vector beam is expected to be far beyond the

diffraction limit of light to achieve higher spatial resolution.

In addition, we are

interested in the development of laser processing utilizing unique

polarization features of vector beams (10.1364/OL.405852).

|

Material processing with an intense laser

field

(metastable nano-particle, mechanical atomic

bond formation) |

|

|

|

|

|

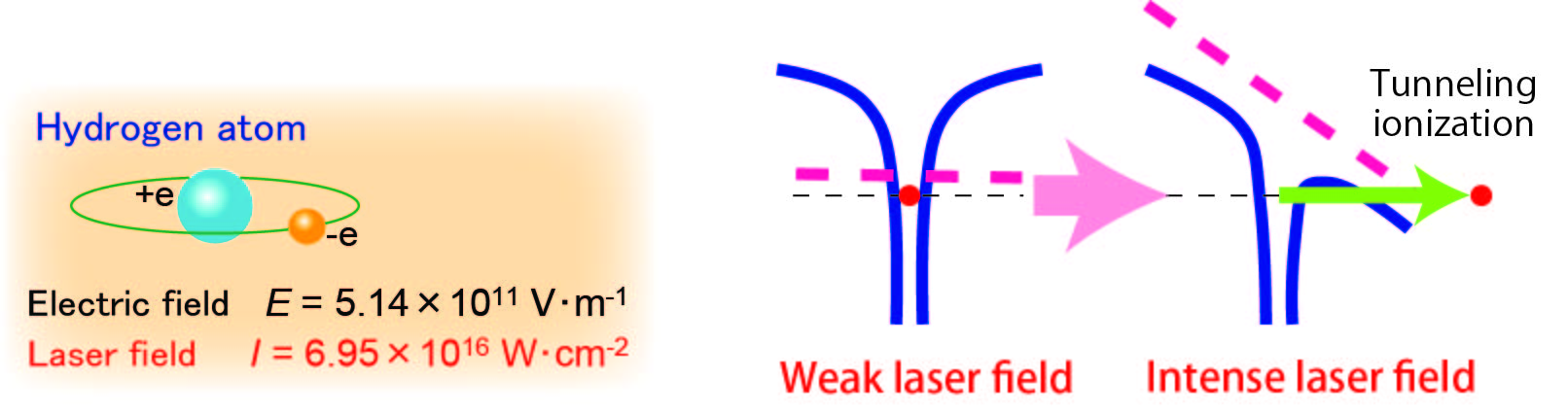

An intense laser field beyond 1013

W/cm2 can be produced by focusing a femtosecond laser pulse.

Irradiation of this intense field to materials produces high-temperature

and high-density plasma because of multi-photon absorption, avalanche

ionization or tunneling ionization. Light field around 1017

W/cm2 is comparable with the Coulomb field inside hydrogen

atom. We are exploring this intense laser field for the synthesis of

metastable alloy nano-particles and mechanical atomic bond formation by

laser shock wave.

|

|

|

|

|

|

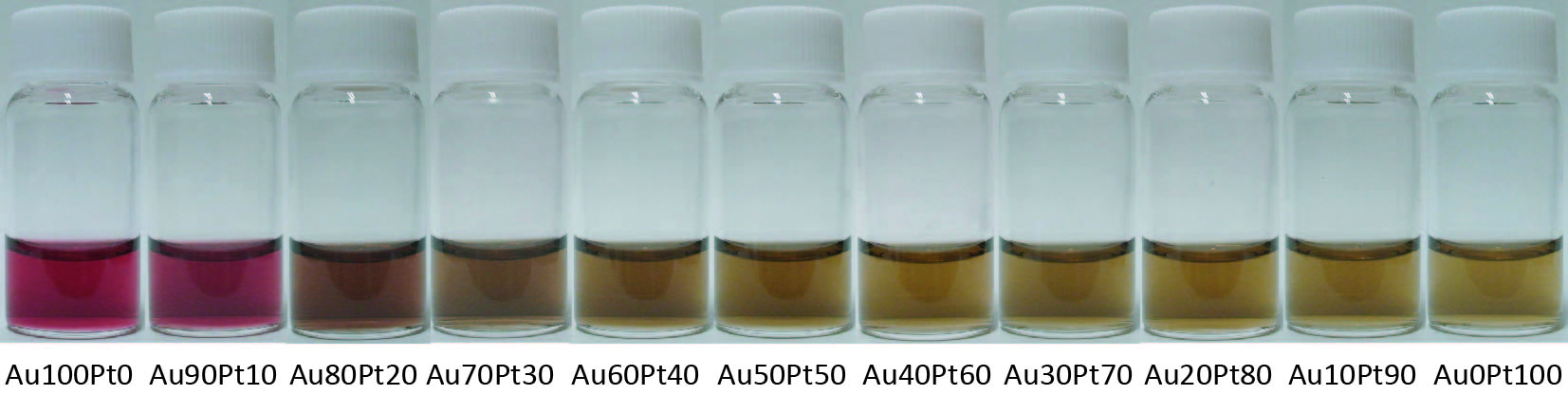

Femtosecond laser irradiation of aqueous

solutions of chloroauric acid or chloroplatinic acid induces the

formation of gold or platinum nanoparticles due to the reduction of

metal ions by solvated electrons and hydrogen radicals generated by

photo-dissociation of water molecule. While bulk alloy of gold and

platinum is phase separating, nanoparticles sybthesized by the

irradiation of mixed aqueous solution of gold and platinum metal ions

are solid solution

(10.14356/kona.2022002).

Formation of the metastable solid solution nanoparticles was observed

even for high entropy alloy nanoparticles of Au-Pt-Rh-Pd-Ir system.

|

|

|

|

Intense laser

irradiation of materials are predicted to produce an ultra-high pressure

up to 1 TPa (107 atm) due to laser-induced shock wave induced

by rapid expansion of plasma in the material. Because this

ultra-high pressure propagates in one direction, anisotropic phase

transition of materials and simple atomic bond formation between

molecules are expected (10.1002/cphc.202000563).

We are challenging phase transition of carbon particles and mechanicla

synthesis of hydrocarbon molecules.

|

|

| Electron beam control by optical beam |

- Phase front transfer from an optical beam to an electron

beam

|

|

|

|

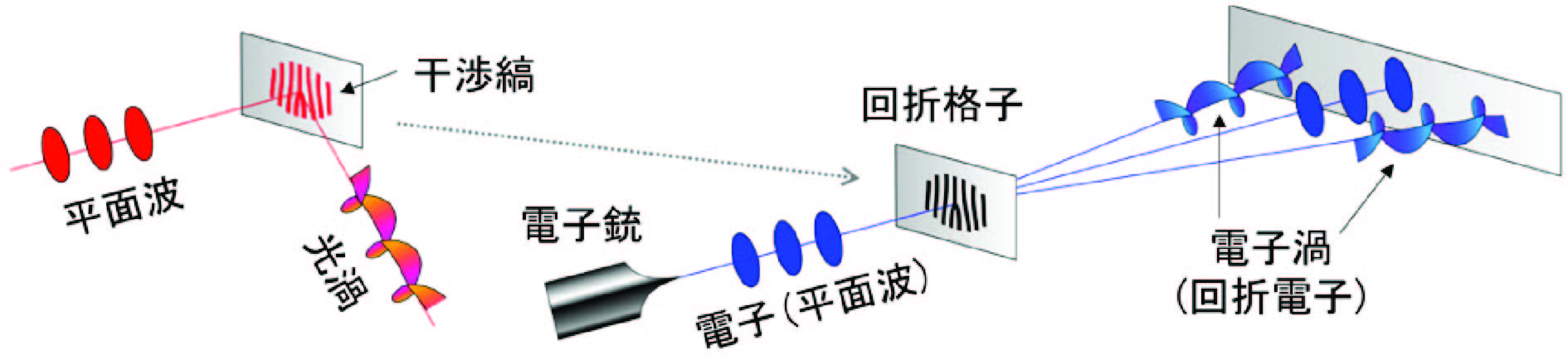

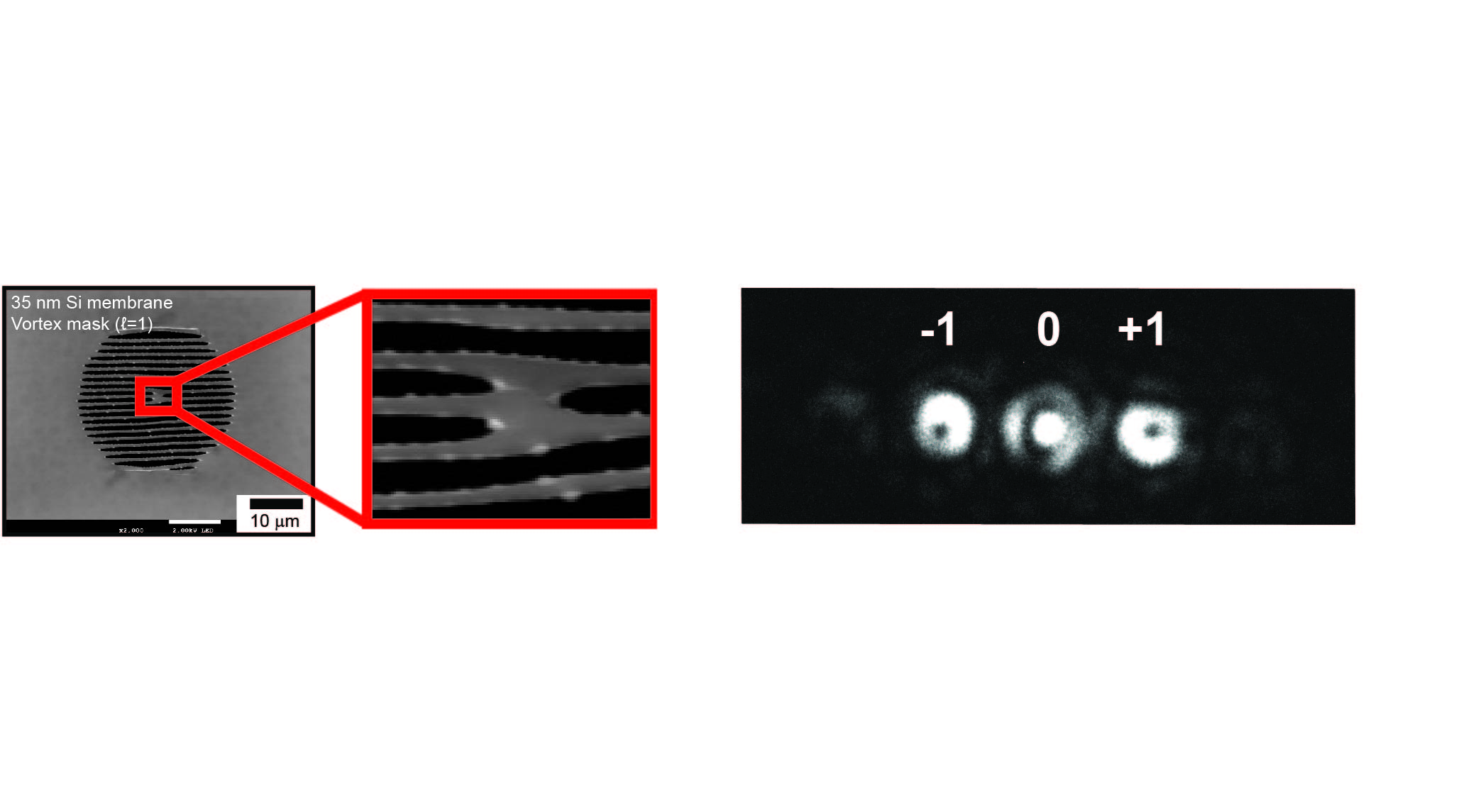

Development of base

technology to control an electron beam by an optical beam is in

progress. As a first step, a phase front transfer technique from optical

wave to electron wave intermediated by materials is being developed. For

example, a hologram was formed by the interference processing of

ultrathin film with an optical plane wave and an optical vortex beam.

The processed thin film can work as a phase hologram for the generation

of a vortex electron beam. In this process, a free-standing thin film

with the thickness of 10 nm was processed by a single laser shot (10.1364/OE.400941).

This process is high-speed and low-cost compared with focused ion beam

(FIB) technique. Because light has much lower kinetic momentum, the

process damage can be dramatically reduced.

|

|

|